Services

Mechanical equipments supplying, precision mechanics according to customer drawings

Precision CNC machining requires engineers very good at their profession. From the first step, if they make any mistake in reading drawing, product details would not be constructed exactly. Base on skilled engineers who have experience and knowledge of many product lines; modern machines and strict monitoring process, PV - VINA is confident to provide products done precisely according to customer requirements.

Install production lines

After receiving customers' requests, PV - VINA will make a small survey at customer’s factory, then discuss more detail with customer about the process and implementation costs.

Manufacture stainless steel equipments, cabinet, rack, and device for clean room

PV - VINA specializes in manufacturing:

- Stainless steel equipments, cabinets, shelves and equipments for clean room according to customer’s order or drawing

- Industrial equipments, stainless steel shelves such as: multi-level stainless tables, frozen tables, cool tables, industrial drying ovens, shelves, cabinets, etc

Manufacture molds, jigs

- Design and manufacture molds such as: plastic molds, stamping die & mold, jig and tool parts

- Molds for rubber industry, silicone injection molds

- Aluminum extrusion molds

Manufacture Aluminum Profile according to customer sample or drawing

At PV - VINA, we start the production process by melting scrap and primary ingot to cast billets from seven to sixteen inches in diameter. The billets are then extruded in small, medium, and large presses. For high volume jobs we use custom machines for optimal efficiency.

Supply industrial rack and cabinet

Sturdy, quality storage shelves and cabinets are made from stainless steel provide storage suitable for industrial and technical environments. Shelves and cabinets are designed and manufactured according to the customer requirements.

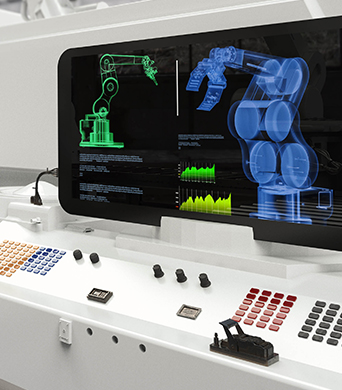

Provide CIM (Computer Integrated Manufaturing) and automation solutions for electronics industry and mass production manufacturing

Computer-integrated manufacturing (CIM) refers to the use of computer-controlled machineries and automation systems in manufacturing products. CIM combines various technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) to provide an error-free manufacturing process that reduces manual labor and automates repetitive tasks. The CIM approach increases the speed of the manufacturing process and uses real-time sensors and closed-loop control processes to automate the manufacturing process. It is widely used in the automotive, aviation, space and ship-building industries.

Mechanical and Electrical (ME) Contractor and Heating Ventilation Air conditioning (HVAC) contractor

We specializes in:

- Water supply system and Drainage system

- Mechanical Electrical Refrigeration

- Chiller, Cooling Tower

- Heating, Ventilation and Air conditioning (HVAC) system for factory